ZZ Industrial (shanghai) Co.,Ltd

|

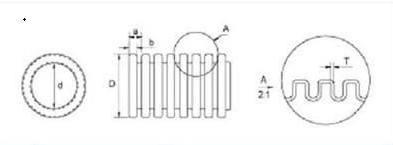

spec

|

weight(g/meter)

|

Inner

diameter

|

Outer

diameter

|

thickness

|

Depth

of Ripple

|

|

20MD

|

60g/meter

|

15(+0.1)(-0.4)mm

|

20(+0.1)(-0.3)mm

|

2.5mm

|

1.5mm

|

|

25MD

|

110g/meter

|

20(+0.1)(-0.5)mm

|

25(+0.1)(-0.4)mm

|

2.5mm

|

1.5mm

|

|

32MD

|

155g/meter

|

25(+0.1)(-0.5)mm

|

32(+0.1)(-0.4)mm

|

3.5mm

|

2.5mm

|

|

40MD

|

190g/meter

|

32(+0.1)(-0.5)mm

|

40(+0.1)(-0.4)mm

|

4mm

|

3mm

|

|

50MD

|

230g/meter

|

42(+0.1)(-0.5)mm

|

50(+0.1)(-0.4)mm

|

4mm

|

3mm

|

|

20HD

|

100g/meter

|

14(+0.4)(-0.1)mm

|

20(+0.1)(-0.3)mm

|

3mm

|

2mm

|

|

25HD

|

155g/meter

|

18(+0.4)(-0.1)mm

|

25(+0.1)(-0.4)mm

|

4mm

|

3mm

|

|

32HD

|

210g/meter

|

24(+0.4)(-0.1)mm

|

32(+0.1)(-0.4)mm

|

4mm

|

3mm

|

|

40HD

|

230g/meter

|

31(+0.4)(-0.1)mm

|

40(+0.1)(-0.4)mm

|

4.5mm

|

3mm

|

|

50HD

|

320g/meter

|

41(+0.4)(-0.1)mm

|

50(+0.1)(-0.4)mm

|

4.5mm

|

3mm

|

Tags: Flexible PVC Hose | Flexible Electrical Tubing | highly flexible wire | Flexible Corrugated Electrical Conduit Pipes | Flexible Pvc Electrical Pipe

Tags: plastic pipe factory | pvc electrical flexible hose | hdpe corrugated pipe | corrugated hose | cable conduit